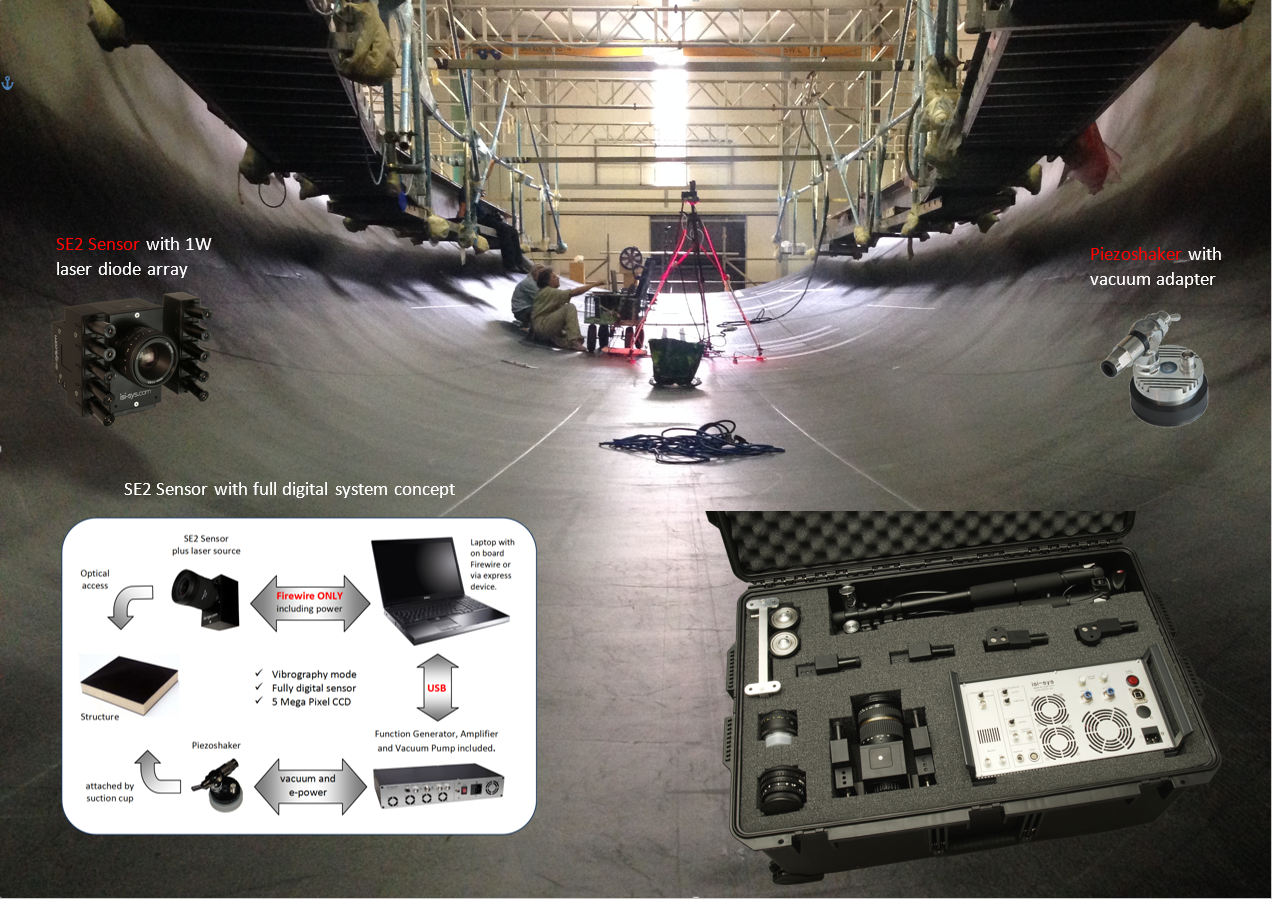

Marine NDE (Spain) used the technical advantages of our Shearography-System especially in combination with the dynamic excitation for non-destructive examination (NDE) of large areas such as complete yacht hulls (see image below). The hull with a lenghts of 30,5m was a carbon-firber-composite and part of high performance sailing yacht in build. Because of the full-field method (100% of the inspected area is examined), the testing of the entire hull required only 240 shots, in three workdays.

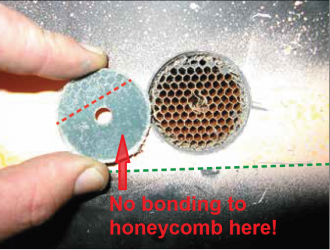

The yacht hull consists of a sandwich construction, where are in particular used honeycomb cores (NOMEX).

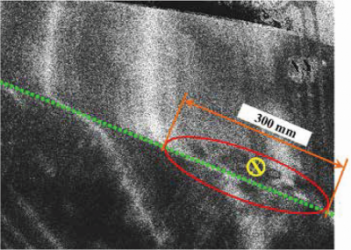

On the left — A shearogram of a detected bonding defect (in red oval). The yellow X marks the location of the core sample shown at the right. The destructive test confirms the shearogram’s indication that there is a significant never-bond between the honeycomb core material and the film adhesive in this area.