Application examples of a special stereomicroscope in combination with Vic-3D digital image correlation on electronic components.

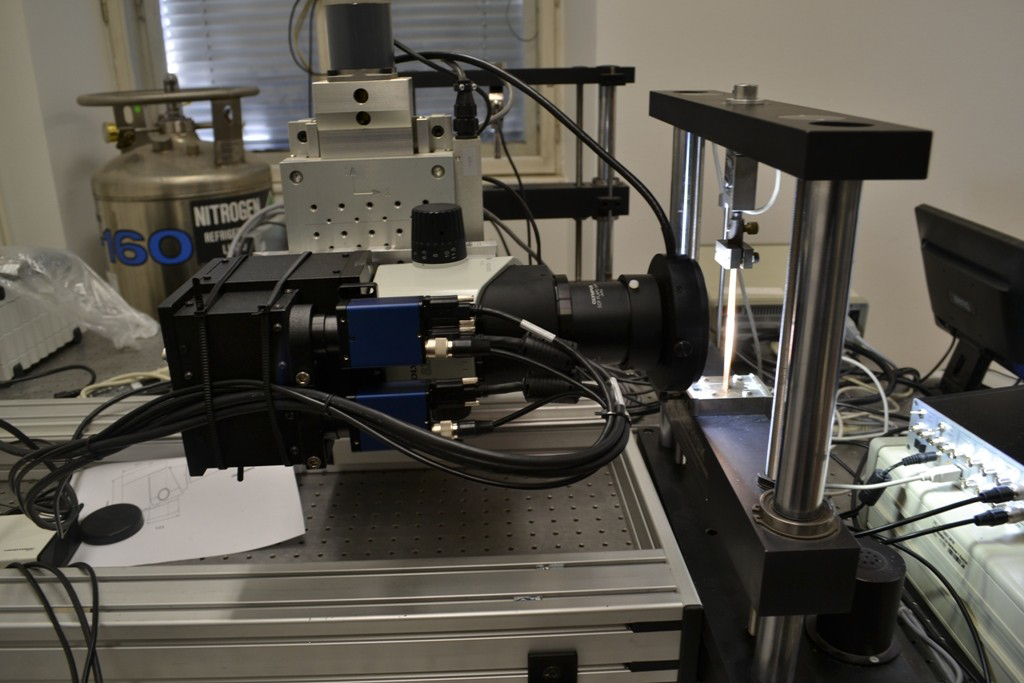

Image 1: Measurement setup

Measurement set up: Stereo microscope mounted on x‑y-z-microtable (backside) and tensile machine (right).

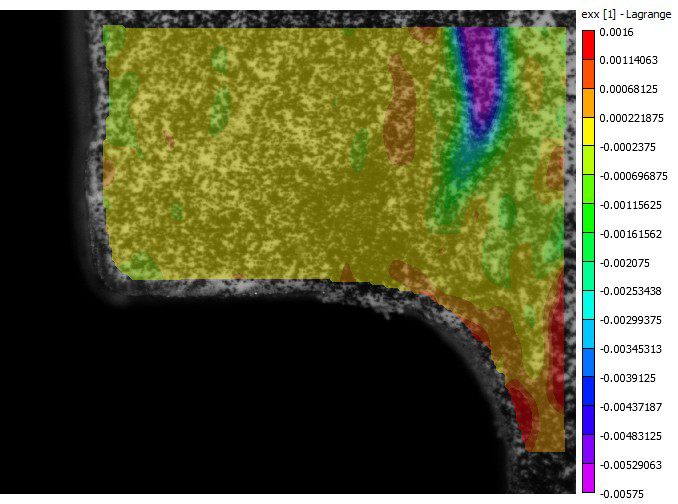

Image 2: Strain in x‑direction

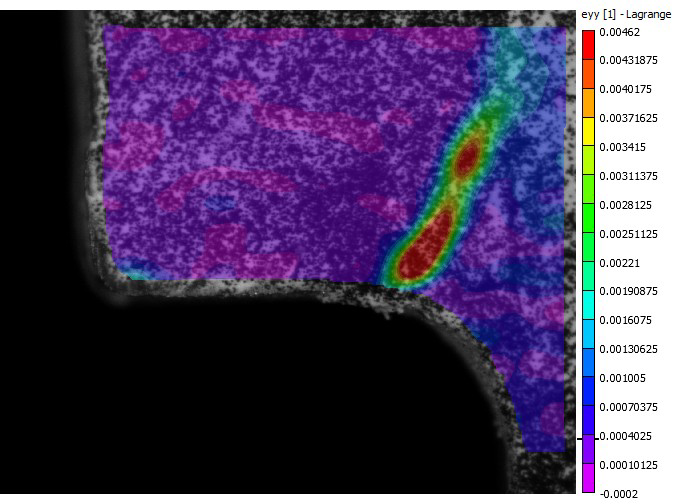

Image 3: Strain in y‑direction

Strain distribution of a half cut capacitor-chip (left part) and its soldering area (round section). The board is under

bending load. The board is vertical on the right sight of the image. The local red area is showing a crack in the

soldering part. Image area approx. <2mm.

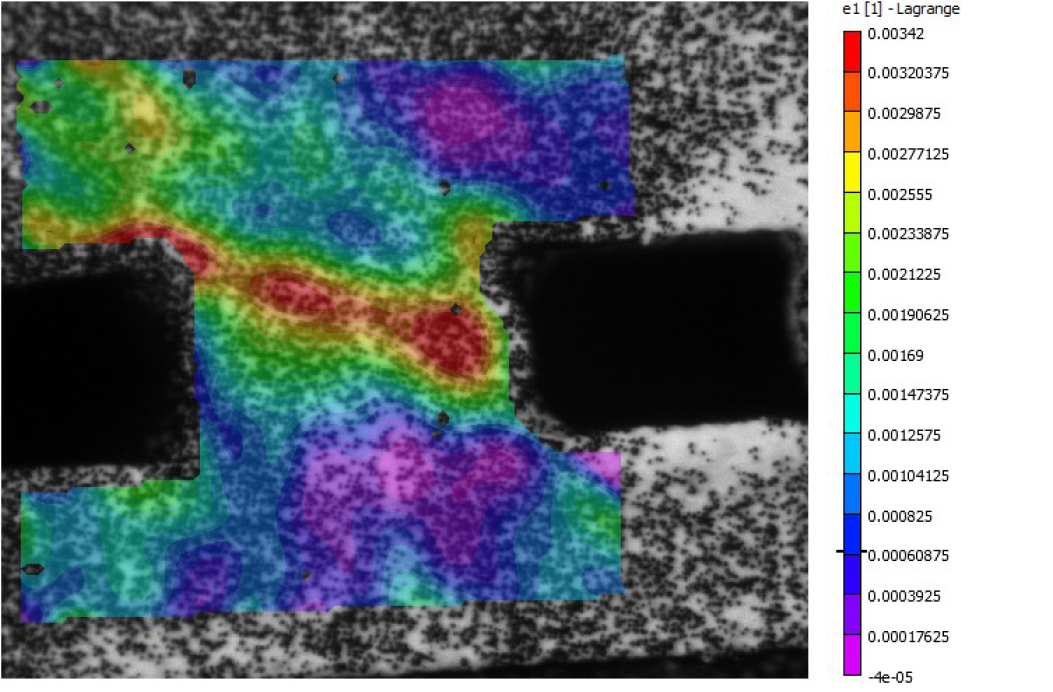

Image 4: The main strain of measuring a solder ball d=300µm under horizontal shear stress is shown.