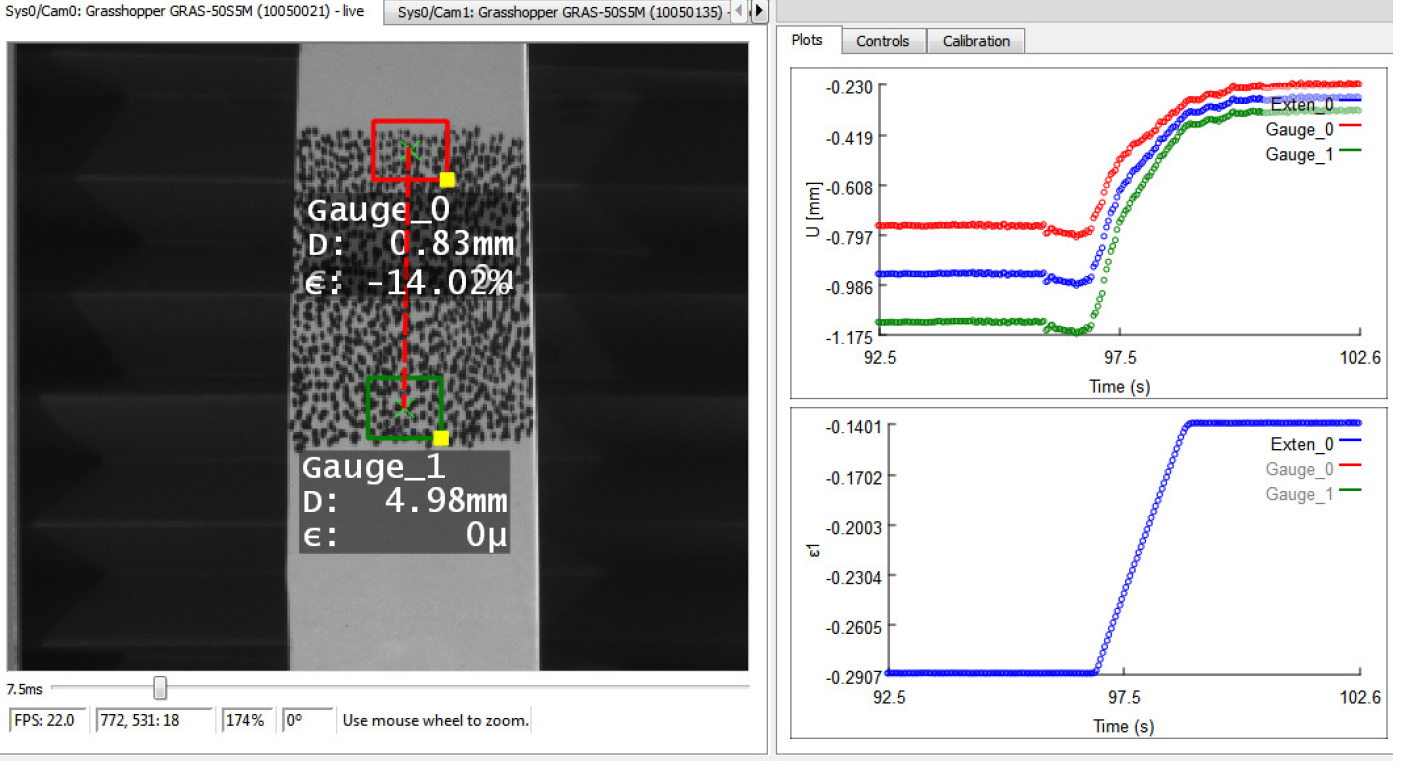

Vic-Gauge uses our optimized 2‑D and 3‑D correlation algorithms to provide real-time displacement and strain data for mechanical testing. Think of this tool as a set of virtual strain gauges: Data can be retrieved for multiple points and plotted live against analog load inputs. Results are saved for every analyzed point, and full images may be saved for full-field analysis in Vic-2D or Vic-3D.

Measurement System Feature Overview

The Vic-Gauge 3D system is offered as a turnkey strain measurement solution that doubles as a video extensometer and virtual strain gauge. The system performs a three-dimensional digital image correlation (DIC) analysis on a pair of images in real-time, processes the data, an then outputs a control signal. The measurements are displayed graphically, but also as virtual gauges values. The system utilizes the same robust and precise algorithms found in the Vic-3D system, and the same ease of use.

General Features:

- Real-time measurement of strain and displacement at one or many discrete points

- Measure strain data at points, or use virtual extensometers to connect locations

- Analog value inputs for real-time load vs. strain reporting

- Dual BNC analog outputs for non-contacting strain or displacement control of test

frames, forming machines, etc. - Each gauge measures

- X, Y, & Z coordinates

- X, Y, & Z displacement

- Full strain and shear tensor

- First and second principal strains

- Full test setup can be saved as a project for fast, consistent repeated tests