The Vic-3D HS™ system allows for measurement of very high speed events. As with all of our Vic-3D systems, surface displacements and strains can be measured in 3D. Vic-3D HS systems instead include two fully-integrated high speed cameras.

High-Speed cameras are very useful for the qualitative assessment of high speed events, however, it can be very tedious to obtain quantitative data from images obtained this way. Marker tracking software helps with this problem, but can only track movement, and does so for a relatively small number of points. In addition, it is normally not possible to accurately measure movements toward or away from the camera.

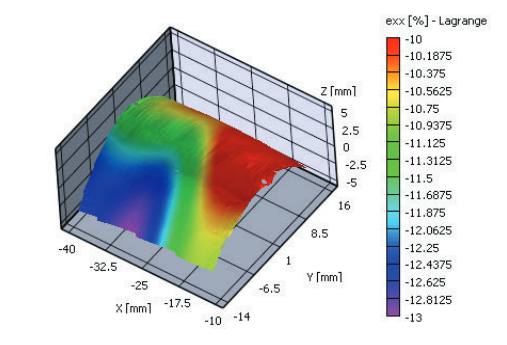

Vic-3D HS provides all the benefits of 3D Digital Image Correlation in a system that includes fully-integrated high-speed cameras. Both movement and strain can be tracked for every pixel within the field of view. And, since this data is calculated in 3 dimensions, it also includes any displacements directly toward or away from the cameras. All calculations are done quickly and automatically by the included software.

Non-Contact

Non-Contact

- No mechanical interaction with your sample

- Eliminates the need for strain gauges, LVDTs, extensometers, etc.

- Fast and easy sample preparation

- Rigid body motion can be easily removed

- Measure dynamic mechanical properties AND vibration at the same time

User-Friendly

- No optical isolation table needed

- Robust system calibration with automatic target spacing detection

- Remotely control cameras with an iOS or Android device

- Cut & paste graphs and plots into any MS Windows application

- Fast data processing with intuitive inspection and extraction too

Full-Field Measurement

Full-Field Measurement

- Eliminates the need for precise strain gauge placement

- Up to 4,000,000 data points possible

- Automatically identify strain concentration locations, even in complex structures under complex loading conditions

- Fast data processing: up to 55,000 data points/second

Application examples for the Vic-3D high speed system:

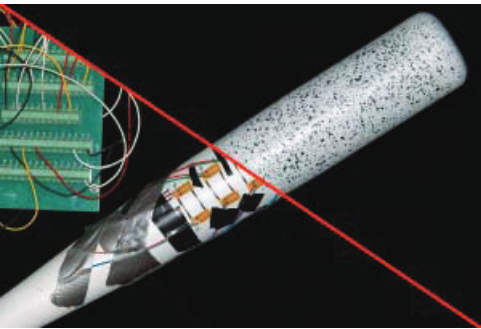

Operation mode analysis on a mobile phone;

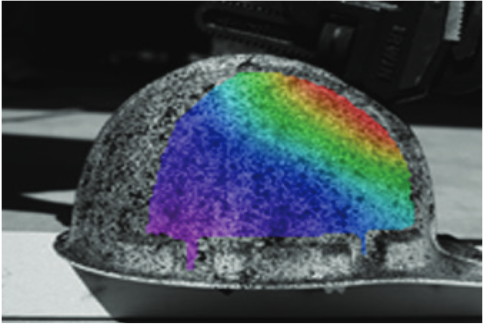

Vibration Analysis of a Brake Disc;