Aerospace Application Example

Airbus has built a reputation for innovative aircraft, recognized around the world for their safety and efficiency. All of these attributes are driven by a top-notch testing program, whose innovative practice are evidenced by their use of the Vic-3D measurement system.

Airbus has built a reputation for innovative aircraft, recognized around the world for their safety and efficiency. All of these attributes are driven by a top-notch testing program, whose innovative practice are evidenced by their use of the Vic-3D measurement system.

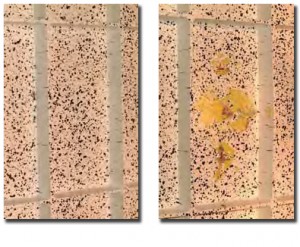

One of the goals of the Airbus testing program is to characterize the structural damage caused by collisions between the aircraft and small projectiles such as birds and other ground based debris, and to ensure that the structural integrity of the aircraft is maintained.

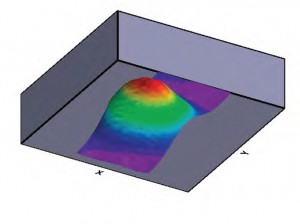

This type of event can be reproduced by firing a variety of different types of projectile at a piece of aircraft structure at a high velocity. The results obtained can be used to compare with computer models of the structure under impact loads, leading to more highly optimized and safer designs.

Dr. Richard Burguete, experimental mechanics specialist at Airbus UK since 1997, explains the benefits of this approach as follows: “The VIC-3D system allows us to be sure we have captured all of the relevant data, some of which might have otherwise been unobtainable.”

Dr. Richard Burguete, experimental mechanics specialist at Airbus UK since 1997, explains the benefits of this approach as follows: “The VIC-3D system allows us to be sure we have captured all of the relevant data, some of which might have otherwise been unobtainable.”