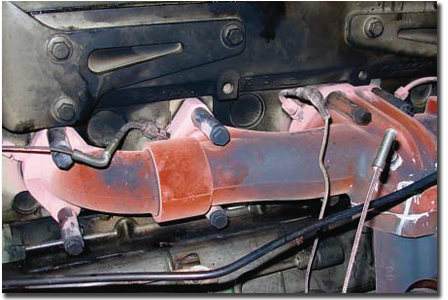

The engineers at Cummins design and test their engines to withstand real-world conditions, ranging from military deployments to heavy-duty industrial sites. Cummins engineers want to know exactly how their parts are deforming under the combination of thermal and mechanical loads. This means they’ve got to perform their tests with the engines running – and hot.

The engineers at Cummins design and test their engines to withstand real-world conditions, ranging from military deployments to heavy-duty industrial sites. Cummins engineers want to know exactly how their parts are deforming under the combination of thermal and mechanical loads. This means they’ve got to perform their tests with the engines running – and hot.

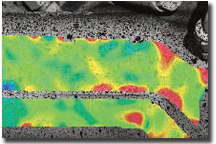

Because of the complex strain fields produced under these conditions, conventional gauges cannot satisfy Cummins’ requirements. FEA simulations are also limited, due to the uncertain boundary conditions. With the Vic-3D system, Cummins engineers are able to obtain detailed three-dimensional strain measurements. These measurements are made under real loading conditions while the engine is running. In addition, the Vic-3D system is easy to set up and can measure both small parts and large assemblies.

.….….….….….….….….….….….….….….….….….….….….….…..

Paul Gloeckner, senior research engineer at Cummins, explains the usefulness of the Vic-3D system as follows: “This tool allows us to make measurements that were previously not possible. It has also allowed us to considerably reduce the time required for these tests.”