The video shows the application of a stereo image correlation (phase synchronized) for a three-dimensional displacement measurement or movement analysis (Vic-3D).

The used stereo camera system is based on two 5 Mpixel cameras with a frame rate of 6Hz (at full resolution) in combination with the isi-sys synchronization and trigger device for stroboscopic observation of periodic events.

X

Four measurement areas (hydraulic cylinder — below, wheel hub — left, swingarm — middle and linear unit — right above) with speckle patterns were monitored for the evaluation. The vector arrows represent the current displacement state.

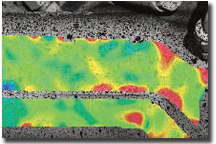

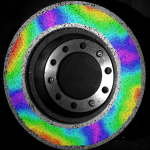

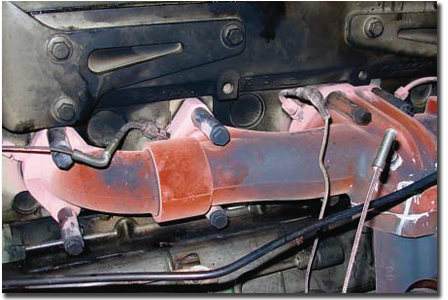

The engineers at Cummins design and test their engines to withstand real-world conditions, ranging from military deployments to heavy-duty industrial sites. Cummins engineers want to know exactly how their parts are deforming under the combination of thermal and mechanical loads. This means they’ve got to perform their tests with the engines running – and hot.

The engineers at Cummins design and test their engines to withstand real-world conditions, ranging from military deployments to heavy-duty industrial sites. Cummins engineers want to know exactly how their parts are deforming under the combination of thermal and mechanical loads. This means they’ve got to perform their tests with the engines running – and hot.