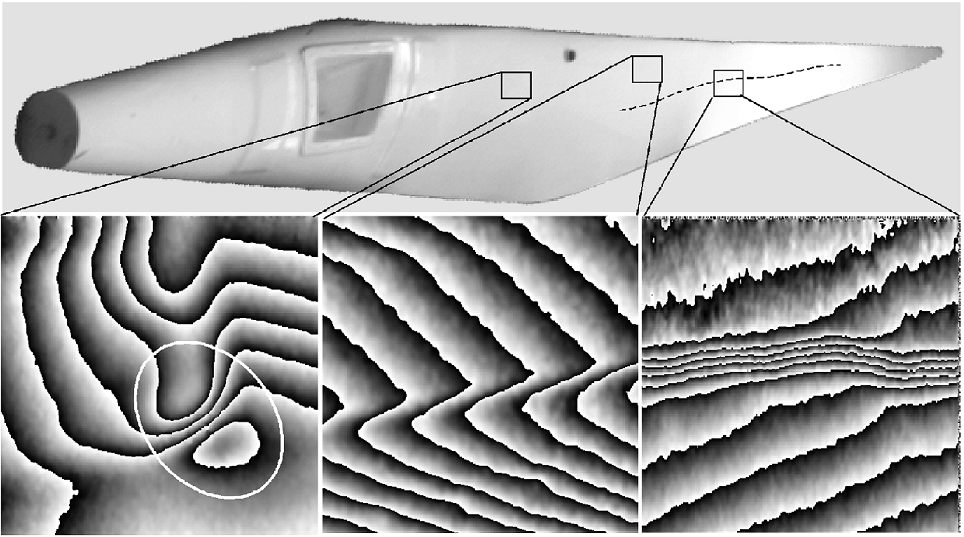

An important area of application of Shearography is non-destructive testing (NDT). Defects become visible on the basis of the measured inhomogeneous deformation- respectively strain-distributions. Beyond the localisation, the defects or the mechanic structure of the object can be further characterised dependent of the spatial distribution. The identification of material parameters of damaged areas is possible as well in combination with fem-models.

Application examples, use the links for detailed information:

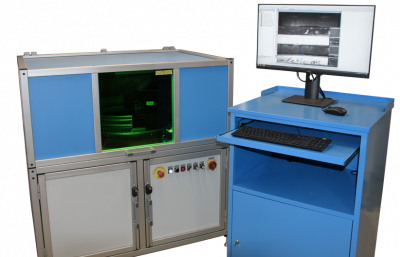

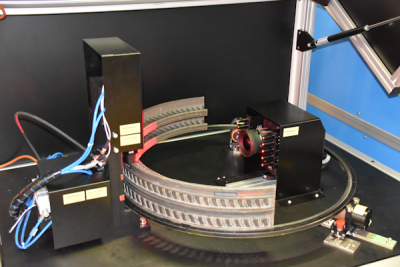

Automated test station

Automated NDT on guide blade rings of air turbines

Automated NDT system for filament wound tubes

Load by dynamic excitation

Dynamic loading on rudder blade

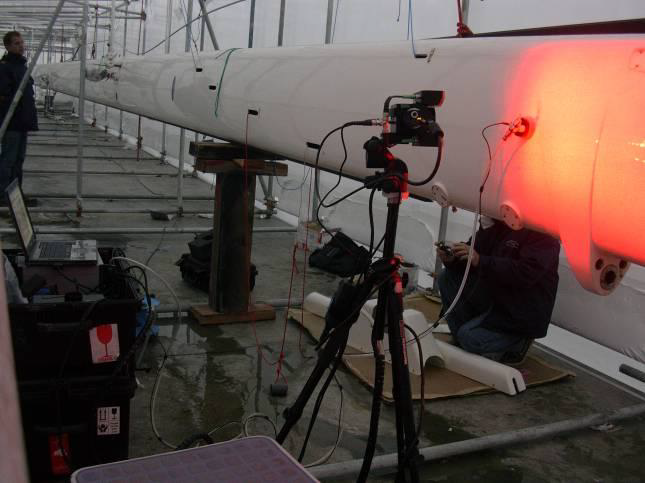

Dynamic loading on a yacht mast

Dynamic excitation on a spacecraft

Dynamic loading on a wind turbine blade and resin bridges

Dynamic loading on a large yacht hull

Load by change of pressure

NDT on wind rotor blades

Load by vacuum

Vacuum loading on battery packs