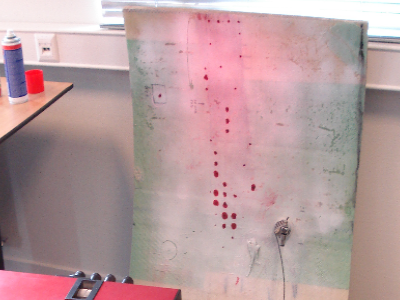

Analysis of a wind turbine blade

The test panel was an original section of a wind turbine blade with a defect (a foam block with bridges). Previously the defect was located by infiltration of color through small drilled holes. The sample is examined non-destructively by the SE-Sensor.

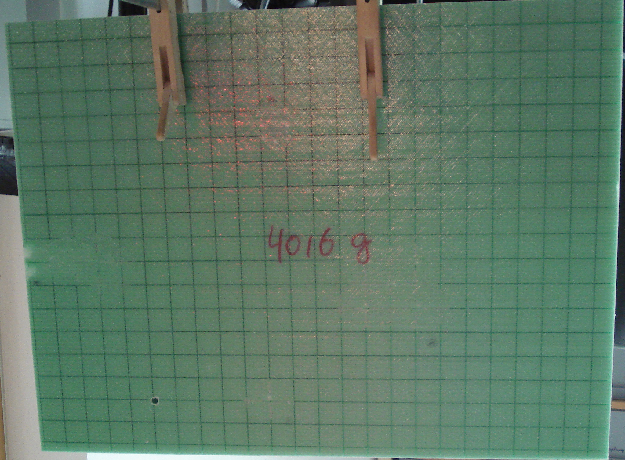

left: Set-up

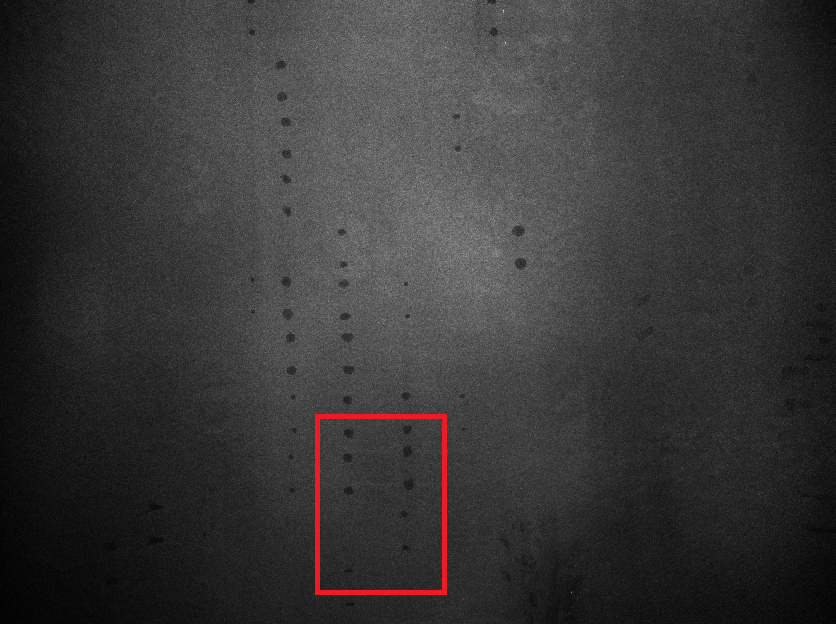

right: Time average result at frequency of 2569Hz showing the debonding area.

left: Live view of surface including shearing.

left: Live view of surface including shearing.

right: Time average measurement from the marked area in the live image.

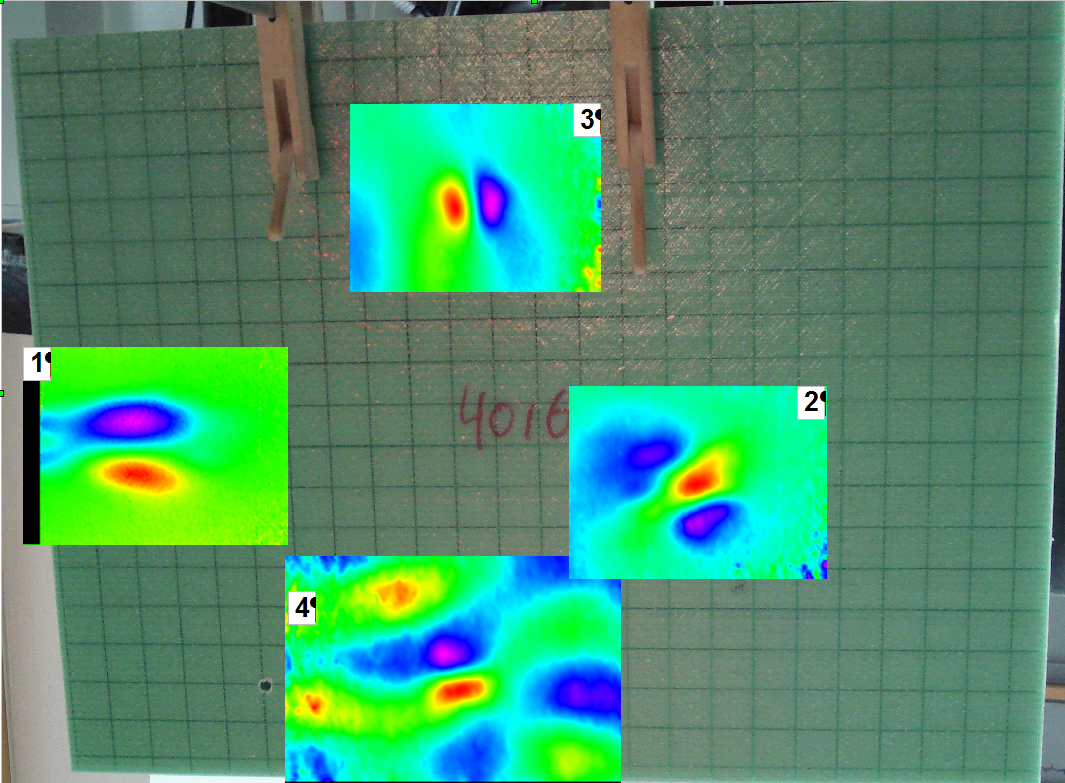

De-bonding of resin bridges

A GFRP sandwich with foam blocks and resin bridges should be examined. The detection of the defect type und structure is very quick and reliable in this case, because the defects are visible, not only at their local natural frequencies, but also due to their forced deflection shapes over a wide frequency bandwidth.

The excitation frequencies of the selected measurements are 1398 Hz (1), 3133 Hz (2), 2442 Hz (3) and 4906 Hz (4) — numbering in following images: